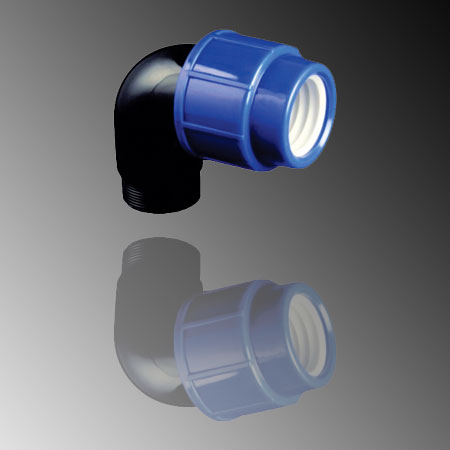

Product Overview:

The Male Thread Elbow is a crucial plumbing fitting designed to create a 90-degree angle in piping systems. Featuring external male threads, it allows for seamless connection with female-threaded pipes or fittings, facilitating directional changes in plumbing, HVAC, and industrial applications. This fitting is essential for routing pipes around obstacles and optimizing system layout.

Key Features:

- Durable Construction: Manufactured from high-quality materials such as brass, stainless steel, or high-grade plastic, ensuring durability, resistance to corrosion, and longevity.

- External Male Threads: Equipped with male threads for secure connection to female-threaded pipes or fittings, accommodating various sizes and threading standards.

- 90-Degree Angle: Designed to provide a sharp 90-degree turn in the piping system, enabling efficient routing and direction changes.

- Leak-Proof Design: Engineered to offer a tight seal, minimizing the risk of leaks and maintaining system pressure.

Specifications:

- Material Options: Brass, stainless steel, high-grade plastic

- Design: 90-degree elbow with external male threads

- Size Range: Available in various sizes to fit different pipe diameters

- Thread Type: Compatible with standard threading types, including NPT, BSP, and more

Benefits:

- Directional Routing: Allows for effective redirection of pipes at a 90-degree angle, optimizing system layout and accommodating space constraints.

- Secure Connection: Provides a reliable and leak-proof connection with female-threaded components, ensuring system integrity.

- Durable Performance: Constructed from robust materials to withstand pressure and resist environmental factors.

- Versatile Use: Suitable for a wide range of applications, including residential, commercial, and industrial systems.

Installation:

To install the Male Thread Elbow, align it with the female-threaded pipe or fitting, screw it on securely, and ensure a tight connection. Use appropriate sealing materials or thread tape if necessary to prevent leaks and ensure a proper seal.

| Size | D | d | d1 | G | L |

|---|---|---|---|---|---|

| 20 x 1/2″ | 44 | 21 | 12 | 1/2″ | 14 |

| 20 x 3/4″ | 44 | 21 | 17 | 3/4″ | 16 |

| 25 x 1/2″ | 56 | 26 | 12 | 1/2″ | 14 |

| 25 x 3/4″ | 56 | 26 | 17 | 3/4″ | 16 |

| 32 x 1/2″ | 65 | 33 | 12 | 1/2″ | 14 |

| 32 x 3/4″ | 65 | 33 | 17 | 3/4″ | 16 |

| 32 x 1″ | 65 | 33 | 22 | 1″ | 19 |

| 40 x 1-1/4″ | 80 | 41 | 30 | 1-1/4″ | 21 |

| 40 x 1-1/2″ | 80 | 41 | 34 | 1-1/2″ | 21 |

| 50 x 1-1/4″ | 92 | 51 | 30 | 1-1/4″ | 21 |

| 50 x 1-1/2″ | 92 | 51 | 34 | 1-1/2″ | 21 |

| 50 x 2″ | 92 | 51 | 44 | 2″ | 26 |

| 63 x 1-1/4″ | 114 | 64 | 30 | 1-1/4″ | 21 |

| 63 x 1-1/2″ | 114 | 64 | 33 | 1-1/2″ | 21 |

| 63 x 2″ | 114 | 64 | 46 | 2″ | 26 |

| 75 x 2-1/2″ | 128 | 76 | 59 | 2-1/2″ | 30 |

| 90 x 3″ | 152 | 91 | 70 | 3″ | 33 |

| 90 x 4″ | 152 | 91 | 91 | 4″ | 38 |

| 110 x 4″ | 182 | 111 | 89 | 4″ | 38 |