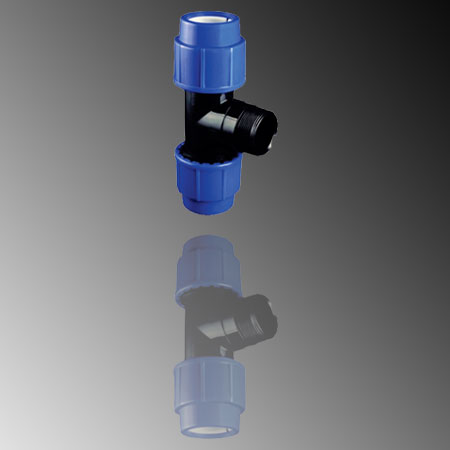

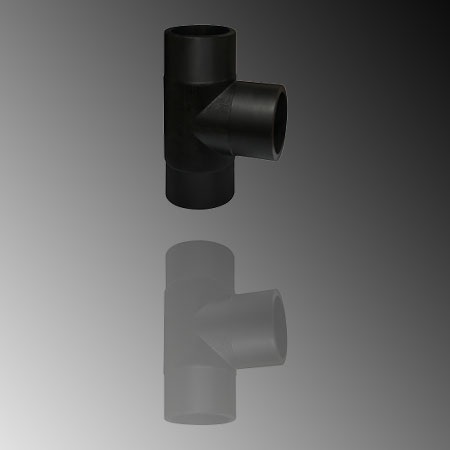

Product Overview:

The Male Thread Tee is a vital plumbing fitting designed to create a three-way junction in piping systems. Featuring external male threads on all three connections, this tee allows for the branching of pipes, enabling efficient fluid distribution in residential, commercial, and industrial applications. It facilitates easy integration and modification of piping layouts.

Key Features:

- High-Quality Construction: Made from durable materials such as brass, stainless steel, or high-grade plastic, ensuring strength, resistance to corrosion, and long-term performance.

- External Male Threads: Equipped with male threads on all three ports, allowing for connection with female-threaded pipes or fittings.

- Three-Way Junction: Provides a 90-degree branching connection, enabling the division or convergence of fluid flow in multiple directions.

- Leak-Proof Design: Engineered for a secure and tight seal, reducing the risk of leaks and maintaining system pressure.

Specifications:

- Material Options: Brass, stainless steel, high-grade plastic

- Design: Tee fitting with external male threads on all three connections

- Size Range: Available in various sizes to fit different pipe diameters

- Thread Type: Compatible with standard threading types, including NPT, BSP, and more

Benefits:

- Efficient Fluid Distribution: Facilitates branching of pipes, allowing for the distribution of fluid to multiple directions or the integration of additional components.

- Reliable Connection: Provides a secure connection with female-threaded components, ensuring system integrity and reducing the risk of leaks.

- Durable Performance: Constructed from robust materials to withstand pressure and resist environmental factors.

- Versatile Use: Suitable for a wide range of applications, including plumbing, HVAC, and industrial systems.

Installation:

To install the Male Thread Tee, align it with the female-threaded pipes or fittings, screw it on securely, and ensure all connections are tight. Use appropriate sealing materials or thread tape if necessary to prevent leaks and ensure a proper seal.

| Size | D | d | D1 | R | L1 | L |

|---|---|---|---|---|---|---|

| 20 x 1/2″ | 44 | 21 | 12.0 | 1/2″ | 14 | 125 |

| 20 x 3/4″ | 44 | 21 | 16.0 | 3/4″ | 16 | 125 |

| 25 x 1/2″ | 56 | 26 | 12.0 | 1/2″ | 14 | 158 |

| 25 x 3/4″ | 56 | 26 | 16.0 | 3/4″ | 16 | 158 |

| 32 x 1/2″ | 65 | 33 | 12.0 | 1/2″ | 14 | 189 |

| 32 x 1″ | 65 | 33 | 22.0 | 1″ | 19 | 189 |

| 40 x 1-1/4″ | 81 | 41 | 30.0 | 1-1/4″ | 21 | 239 |

| 40 x 1-1/2″ | 81 | 41 | 34.0 | 1-1/2″ | 21 | 239 |

| 50 x 1-1/2″ | 92 | 51 | 34.0 | 1-1/2″ | 21 | 262 |

| 50 x 2″ | 92 | 51 | 46.0 | 2″ | 26 | 262 |

| 63 x 2″ | 114 | 64 | 46.0 | 2″ | 26 | 303 |

| 75 x 2-1/2″ | 128 | 76 | 59.0 | 2-1/2″ | 30 | 365 |

| 90 x 3″ | 152 | 91 | 70.0 | 3″ | 33 | 420 |

| 90 x 4″ | 152 | 91 | 89.0 | 4″ | 38 | 420 |

| 110 x 4″ | 182 | 111 | 89.0 | 4″ | 38 | 482 |