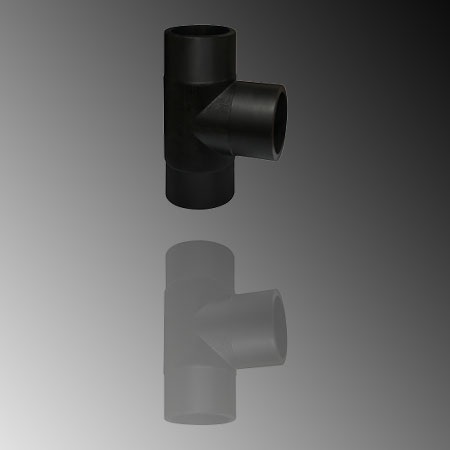

Product Overview:

The Flange is a crucial mechanical component used to connect pipes, valves, pumps, and other equipment in a piping system. Designed for secure and reliable connections, flanges are available in various materials and sizes to accommodate different pressures and temperatures. They provide a stable and leak-proof joint that simplifies assembly and maintenance.

Key Features:

- Durable Construction: Made from high-quality materials such as carbon steel, stainless steel, or PVC, ensuring strength, durability, and resistance to corrosion and high pressures.

- Variety of Sizes and Types: Available in a range of sizes and flange types, including slip-on, weld neck, blind, and threaded, to suit different applications and requirements.

- Leak-Proof Seal: Engineered to create a tight and secure seal, minimizing the risk of leaks and maintaining system pressure.

- Standardized Design: Complies with industry standards such as ANSI, DIN, and JIS, ensuring compatibility and ease of integration with other components.

Specifications:

- Material Options: Carbon steel, stainless steel, PVC

- Design Types: Slip-on, weld neck, blind, threaded, and more

- Size Range: Various sizes to accommodate different pipe diameters

- Pressure Rating: Designed to handle various pressure levels, depending on material and design

- Standards: Conforms to industry standards such as ANSI, DIN, JIS

Benefits:

- Secure Connection: Provides a reliable and stable joint between pipes and equipment, reducing the risk of leaks and ensuring system integrity.

- Durable Performance: Constructed from robust materials to withstand high pressures, temperatures, and environmental conditions.

- Versatile Use: Suitable for a wide range of applications, including industrial, commercial, and residential piping systems.

- Easy Maintenance: Simplifies assembly and disassembly, facilitating maintenance and repairs.

Installation:

To install a flange, align it with the mating flange or equipment, secure it using appropriate bolts and gaskets, and tighten the bolts to achieve a leak-proof seal. Ensure that the flanges are properly aligned to prevent damage and maintain a tight connection.

| Size (mm) | Pressure | ||

|---|---|---|---|

| SDR 11 | SDR 13.6 | SDR 17 | |

| 50 | SDR 11 | / | / |

| 63 | SDR 11 | / | / |

| 75 | SDR 11 | / | / |

| 90 | SDR 11 | / | / |

| 110 | SDR 11 | / | // |

| 125 | SDR 11 | / | / |

| 140 | SDR 11 | / | / |

| 160 | SDR 11 | SDR 13.6 | SDR 17 |

| 180 | SDR 11 | / | / |

| 200 | SDR 11 | SDR 13.6 | SDR 17 |

| 225 | SDR 11 | / | / |

| 250 | SDR 11 | SDR 13.6 | SDR 17 |

| 280 | SDR 11 | / | / |

| 315 | SDR 11 | SDR 13.6 | SDR 17 |

| 355 | / | / | SDR 17 |

| 400 | / | SDR 13.6 | SDR 17 |

| 450 | / | / | SDR 17 |

| 500 | / | SDR 13.6 | SDR 17 |

| 560 | / | / | SDR 17 |

| 630 | / | SDR 13.6 | SDR 17 |

| 710 | / | / | SDR 17 |

| 800 | / | / | SDR 17 |

| 900 | / | / | SDR 17 |

| 1000 | / | / | SDR 17 |